Taber Abrasion Testing Services

TABER ABRASION TESTING TO EVALUATE WEAR CHARACTERISTICS OF COATINGS AND MATERIALS

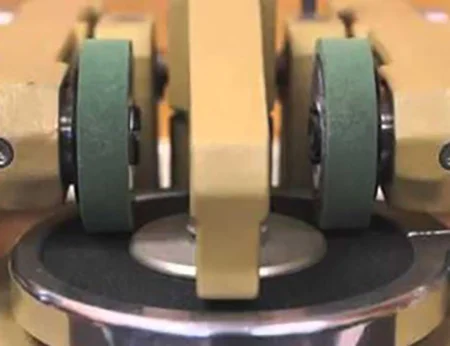

A typical Taber abrasion test consists of a disk-shaped specimen that is placed in constant contact with abrasive wheelS, using predetermined forces to a specified number of cycles to determine wear. The most commonly used standards for these tests are: ASTM D4060, ASTM F1978-12 and MIL-A-8625.

Taber abrasion is a quick and simple way to measure wear resistance and offer sufficient comparable data at a reasonable price. It gives a side by side comparison of several materials or coatings, so you can evaluate which material has better wear resistance under simulated, accelerated wear conditions.

IMR performs a large variety of physical, mechanical, and chemical testing methods to help manufacturers in the aerospace, transportation, and medical device industries verify material properties for critical applications.

For more information on our polymer testing capabilities, click here to request a quote, or click the button below.

Bond Strength

Brookfield Rotational Viscosity

Coefficient of Expansion

Coefficient of Friction

Composite Testing

Compression Set

Compressive Properties (-240ºF to 660ºF)

Dynamic Mechanical Analysis (DMA)

Failure Analysis

Flammability (UL94, FMVSS 302, ISO 3795, SAE J369, ASTM D5132)

Fatigue Testing

Flexural Properties (-240ºF to 660ºF)

Gardner Impact

Glass Transition

Gloss (ASTM D523, D4039)

Hardness Testing (Barcol, Durometer/Shore)

Heat Deflection by TMA (E2092)

Impact Strength

Kinematic Viscosity

Lap Shear Testing

Melt Flow Rate/Index

Melting Point

SEM-EDS for Fillers

Taber Abrasion

Tear Resistance of Films & Sheeting

Tear of Rubbers & Elastomers

Tensile Properties (-240F to 660F)

UV Exposure

RELEVANT ACCREDITATIONS

Click here for a complete list of accreditations and certifications for all IMR Test Labs locations.