Additive Manufacturing Materials Testing Services

IMR's Additive Manufacturing testing lab has expanded capabilities in testing powdered metal characterization and laser-sintered metal testing & analysis to help manufacturers quickly and accurately evaluate their product throughout the design, development, and production phases.

For example, IMR provides comprehensive powder analysis to characterize the starting powder via the following test methods fully:

- Chemical Analysis (ICP-AES, ICP-MS)

- Percent Crystallinity Testing

- Particle Size Testing (Microtrac)

- Morphology Analysis of Density and Flow (XRD, SEM and optical)

A full list of analytical services offered by IMR for Additive Manufacturing is listed below. Or if you're ready for a quote, click the button below.

ADDITIVE MATERIALS TESTING - POWDERS, RAW MATERIALS

Many additive manufacturing (AM) challenges are being overcome through the use of materials testing and analysis. This starts with the need for well-characterized raw materials:

- Powders

- Pastes

- Wires

SLS powders especially need ongoing testing due to the need to reuse unsintered powder without affecting the end product.

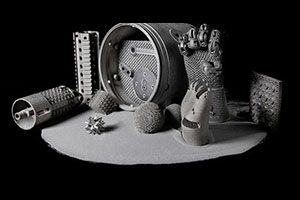

ADDITIVE MATERIALS TESTING- COMPONENTS TESTING

Additive manufactured components testing requires the analysis of a wide array of properties, based not only on the end-use of the part but also the AM process being used to produce them. With the push towards lighter, more durable products created with AM technology, supply chains must ensure that their products meet or exceed physical characteristic specifications of quality.

ADDITIVE MATERIALS TESTING- TAP DENSITY

The testing of density of powders for additive materials manufacturing is done with the tap density test, which is performed by mechanically tapping the powder sample a set number of times. The resulting data measures the tapped density of the powder. Tapped density is measured as a ratio: the mass of the powder in relation to the volume of the powder after it has been tapped. The tapped density ratio measurement is useful in additive materials manufacturing because it ensures that the powders selected for a given application are suitable.

The testing of density of powders for additive materials manufacturing is done with the tap density test, which is performed by mechanically tapping the powder sample a set number of times. The resulting data measures the tapped density of the powder. Tapped density is measured as a ratio: the mass of the powder in relation to the volume of the powder after it has been tapped. The tapped density ratio measurement is useful in additive materials manufacturing because it ensures that the powders selected for a given application are suitable.

ADDITIVE MATERIALS TESTING- GAS PYCNOMETER

A gas pycnometer is used to measure absolute density or skeletal density of a solid. The test is non-destructive and is used on materials that are granular, porous, or irregularly shaped. The testing offers insight into material stability, quality, and purity and is done so quickly and with highly accurate results. The analysis received from a gas pycnometer test is applicable in additive materials manufacturing as an overview of material properties in relation to the applications they may be used for.

A gas pycnometer is used to measure absolute density or skeletal density of a solid. The test is non-destructive and is used on materials that are granular, porous, or irregularly shaped. The testing offers insight into material stability, quality, and purity and is done so quickly and with highly accurate results. The analysis received from a gas pycnometer test is applicable in additive materials manufacturing as an overview of material properties in relation to the applications they may be used for.

ADDITIVE MATERIALS TESTING- APPARENT DENSITY

Apparent density is performed on powders and solids, and measures the density of the material less the void spaces between the particles. The use of materials in the additive materials manufacturing industry is directly impacted by the apparent density measurements of the materials.

Apparent density is performed on powders and solids, and measures the density of the material less the void spaces between the particles. The use of materials in the additive materials manufacturing industry is directly impacted by the apparent density measurements of the materials.

ADDITIVE MATERIALS TESTING - METHODS FOR MATERIAL CHARACTERIZATION

POROSITY

Created when small pockets of air get formed in the body of the part or component being printed. It can be in the form of a process-induced porosity, or a gas-induced porosity. This can lead to cracks and fatigue due to a reduction in the density of the part.

- Testing Methods: Helium Pycnometer, Metallographic Analysis

DENSITY

This measurement is in a direct inverse relationship with porosity. A reduction in density due to porosity can lead to fatigue and cracking when applying pressure. An evaluation of Particle Size Distribution is helpful, since a proportional number of small particles can fill in the gaps around the larger particles, reducing porosity and increasing density.

- Testing Methods: Archimedes, Helium Pycnometer, Microstructure Analysis

CRACKING

When melted metal solidifies, the risk of cracking increases. Careful monitoring of the energy source to keep its output level consistent and moderate during production/printing will help mitigate the potential for damage. The quality and characteristics of the alloy powder are critical in maintaining the integrity of the printed part. Delaminating can also occur when the powder is not melted to an adequate level or escapes to form a re-melting layer under the melt pool.

- Testing Methods: Ultrasonic, Metallography

FUNCTIONAL STRENGTH

In addition to providing incredible flexibility in design, additive manufactured products need to meet strength and durability standards. Mechanical testing offers a variety of methods.

- Testing Methods: Tensile, Fatigue, Fracture Toughness

RESIDUAL STRESS

During the metal 3D printing process, residual stress is created due to the inherent heating/cooling cycles and expansion/contraction. Cracking can occur when the residual stress exceeds the printing material’s tensile strength. The most vulnerable location for this issue is the common interface between the part being manufactured and the build plate.

- Testing Methods: X-Ray Diffraction (XRD), Hole Drilling

ADDITIVE MANUFACTURING PRODUCTION METHODS

SLA- Stereolithography (H3)

DLP- Digital Light Processing

FDM- Fused Deposition Modeling

SLS- Selective Laser Sintering

SLM- Selective Laser Melting

EBM- Electron Beam Melting

Wire Arc Additive Manufacturing

LOM- Laminated Object Manufacturing

BJ- Binder Jetting

MJ- Material Jetting

BENEFITS OF CHOOSING IMR TEST LABS FOR ADDITIVE MANUFACTURING TESTING

- Equipment - IMR Test Labs has invested in state-of-the-art equipment and technology for testing and has expanded capabilities in raw material characterization and finished product testing

- Experience - IMR Test Labs technicians are experts in analyzing materials and processes and has dedicated resources for AM customers in order to get faster turnaround on quotes

- Efficiency - IMR Test Labs is dedicated to fast turnaround on jobs, helping manufacturers make important evaluations quickly and easily

- Quality - IMR Test Labs has a strict control system in place to ensure testing is completed with the utmost integrity

- Accreditations - IMR Test Labs is a Nadcap and A2LA (ISO 17025) approved laboratory and holds accreditations from Boeing, GE, Pratt & Whitney, Rolls Royce, and many more. IMR holds 15 processing approvals from Honeywell, including Atomic Emission Spectroscopy and Microindentation Hardness Testing. View the complete list.

ADDITIVE MANUFACTURING ANALYTICAL SERVICES

CHEMICAL ANALYSIS

Apparent Density

Ash Content

Carney Flow

C, H, O, N, S

Chemical Resistance

Cleanliness Testing

Coating Weight

Contaminant/Corrodent Analysis

Density

DSC Analysis (Melting Point, Glass Transition, % Crystallinity, Degree of Cure, Purity)

Filler Content Analysis

FTIR AnalysisHall Flow

Halogen Analysis (IC)

Heavy Metal Impurities

Hexavalent Chromium

ICP-AES Analysis

ICP-MS Trace Element Analysis

Ion Chromatography (IC)

Material Certification

Mercury AnalysisParticle Size Analysis PercentCrystallinity

Phase Identification

Positive Material ID (On-site PMI available)

Powder Diffraction

Precious Metal AssayScott Flow

SEM/EDX

Sieve Analysis

Trace Element Analysis

Unknown Material ID

X-Ray Diffraction (XRD)

XRF Chemistry

METALLURGICAL ANALYSIS

Case Depth

Failure Analysis

Grain Size

Image Analysis

Inclusion Rating

Intergranular Attack

Intergranular Oxidation

Macroetch/Microetch

Metallography/Materialography

Microhardness (Knoop, Vickers, MacroVickers)

Microstructure

Orientation in Microstructure

Particle Analysis (Distribution, ID, Size)

SEM Analysis

MECHANICAL TESTING

Charpy Impact Testing (-320°F to 450°F)

Creep & Stress Rupture

Fatigue Testing (Axial, Low Cycle, High Cycle, Rotating Beam, Coating Shear)

Fracture Mechanics

Hardness (Rockwell, Brinell)

Heat Aging

Indentation Toughness

ADDITIVE MANUFACTURING VIDEO

DOWNLOAD OUR FREE EBOOK

MATERIALS TESTING FOR THE ADDITIVE MANUFACTURING INDUSTRY

While Additive Manufacturing is a huge growth industry, new technologies are making the choice for raw materials a more complex decision. Taking into account design geometries, operating environments and budget concerns, AM companies have a strong need for accurate materials characterizations to enable them to project a part's design viability and operating durability.

Find out how IMR Test Labs uses a multi-disciplinary approach to Additive Manufacturing testing and analysis. Click here (or on the button below) to download our eBook.