Energy industry producers and their suppliers rely on IMR Test Labs to provide analytical services on the materials needed for power generation equipment and components. From routine checks of raw materials to support R&D efforts, and failure analyses, our labs can provide clear, concise reports, fast turnaround times, and access to our experts before, during and after testing. We provide testing on metals, polymers, fiber-reinforced composites, ceramics, contaminants and corrosion products.

We carry a broad range of accreditations including numerous NQA-1 & NIAC approvals, and we've worked with clients and suppliers in a variety of power generation facilities:

- Nuclear

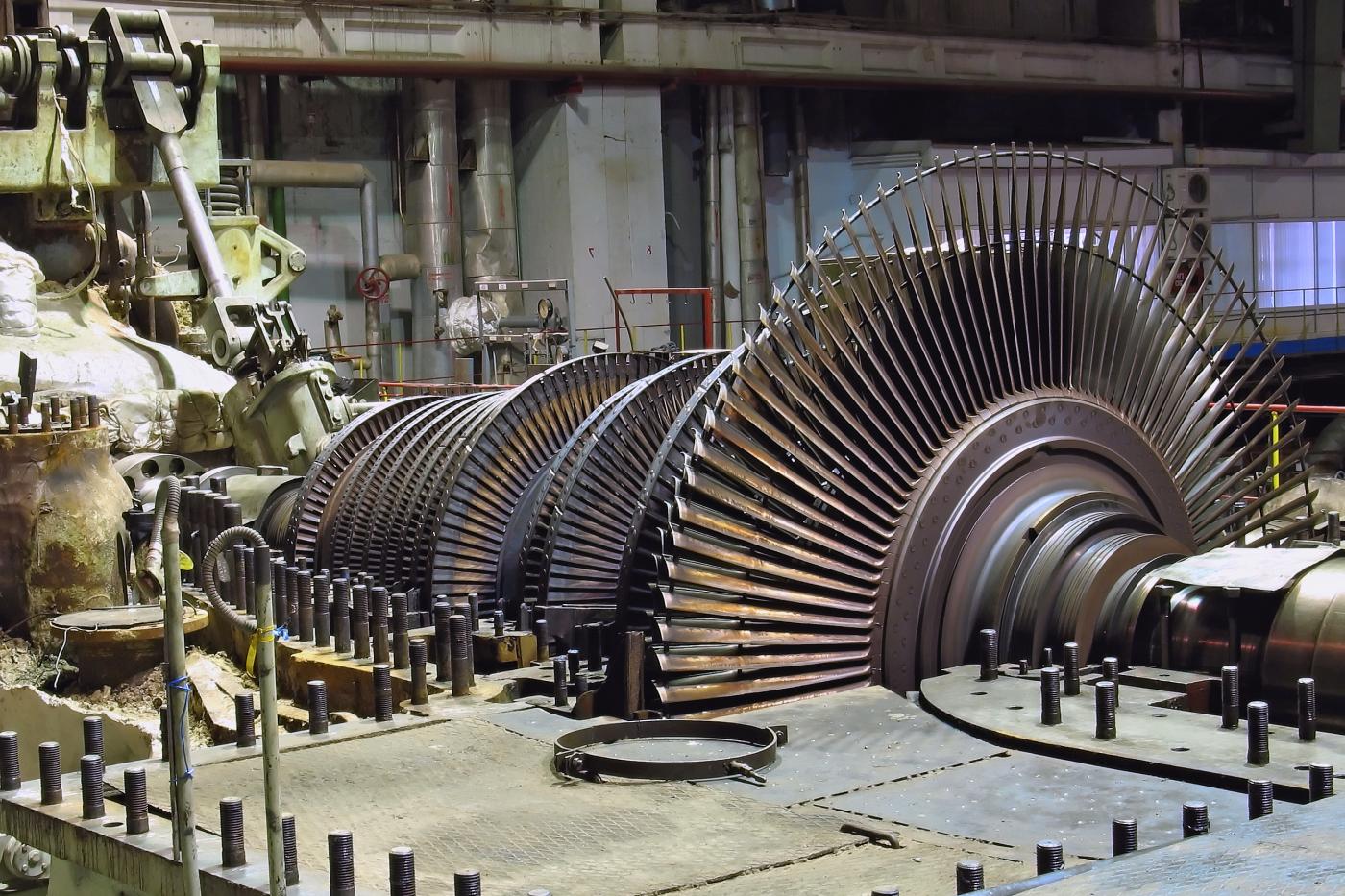

- Steam Turbine

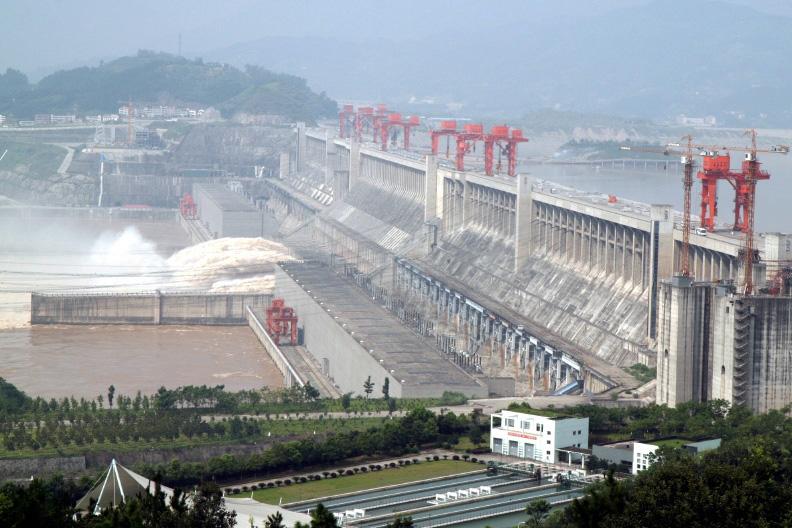

- Hydropower

- Wind Turbine

- Power Transmission

To learn more about IMR's analytical services for the power generation industry, check out our list of services below or request a quote today!

ENERGY INDUSTRY ANALYTICAL SERVICES

Alloy Chemistry

Cleanliness Testing

DSC Analysis

Contaminant Analysis

Elemental Analysis

FTIR Analysis

Hazardous Substances

Heavy Metal Impurities

ICP Chemical Analysis

Ionic Contamination

Metallic Material Verification

N, O, C, S, H

OES Chemical Analysis

On-Site PMI

Polymer Analysis

Rare Earth Elements

SEM/EDS

TGA

Trace Element Analysis

Charpy Impact Testing

Fatigue Testing

Fracture Mechanics

Hardness Testing

High Cycle Fatigue

Hydrogen Embrittlement

Low Cycle Fatigue

Rotating Beam Fatigue

Slow Strain Rate Testing (G129)

Tensile Testing

Weld Inspection/Testing

Corrosion Failure

Fractography

Nonmetallics Failure

Structural Failure

Case Depth

Certified Weld Inspections

Coatings Analysis

Decarburization

Failure Analysis

Grain Size

Inclusion Rating

Intergranular Attack

Intergranular Oxidation

Microhardness (Knoop, Vickers, Macro Vickers)

Microstructure

Particle Analysis (Distribution, ID, Size)

Plating & Coating Analysis

Porosity

Quantitative Image Analysis

SEM Analysis

Surface Topography

Thermal Spray Coating Analysis

Weld Qualifications

Accelerated Weathering

Cyclic Corrosion

Dezincification Testing

Electrochemical Corrosion Simulation

Mercurous Nitrate Testing

Pitting Corrosion Testing

Stress Corrosion Cracking (SCC)

Catalysts

Contaminants

Corrosion Deposits

Pistons

Pump Shafts

Thermal Spray Coatings

Valves

Welds, Brazes and Repair Materials