Composite Layup Evaluation Services

LAYUP EVALUATION OF FIBER REINFORCED COMPOSITES

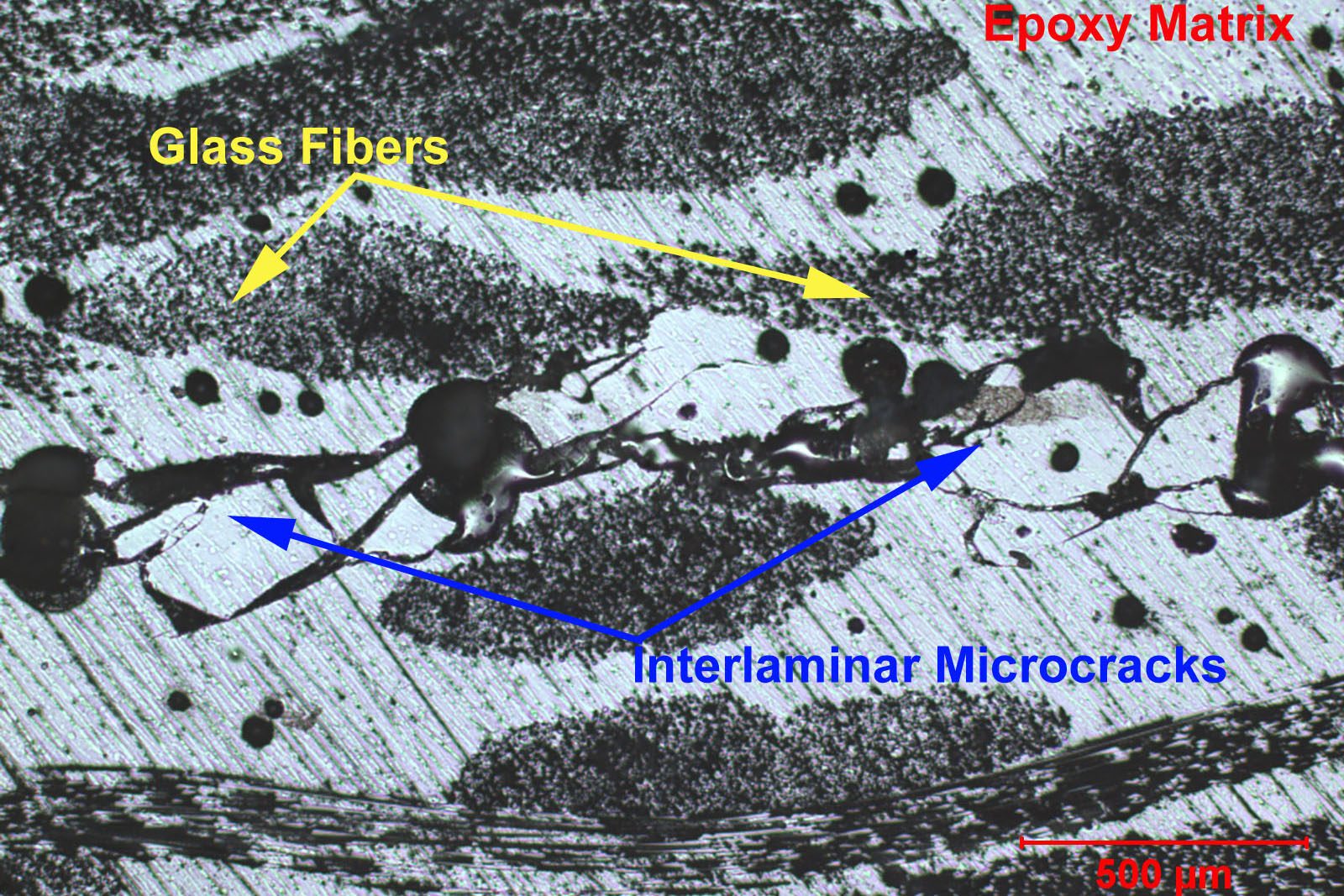

IMR's composites analysis lab utilizes advanced sectioning techniques and digital microscopy to evaluate the layup of composites after curing. Features such as spacing, density of fiber, voiding, and separation can be imaged on large form samples. Digital images allow for numerous micrographs to be stitched together into one mosaic image showing overall layup quality.

Proper layup and curing of composites can strongly influence physical properties such as strength, toughness, hardness, high/low temperature characteristics, or wear resistance. Evaluating these properties helps determine the if the layip meets the needs of the application.

ANALYSIS METHODS

- Optical Microscopy

- Digital Microscopy

- SEM/EDX (Scanning Electron Microscopy / Energy Dispersive Analysis)

- Image Analysis

IMR performs a large variety of physical, mechanical, and chemical testing methods to help manufacturers in the aerospace, transportation, and medical device industries verify material properties.

For more information on our composite analysis capabilities, click here to request a quote, or click the button below.

POLYMER CHARACTERIZATION SERVICES

Accelerated Aging (Heat, Fluids)

Bond Strength

Brookfield Rotational Viscosity

Coefficient of Expansion

Coefficient of Friction

Composite Testing

Compression Set

Compressive Properties (-240ºF to 660ºF)

Dynamic Mechanical Analysis (DMA)

Failure Analysis

Flammability (UL94, FMVSS 302, ISO 3795, SAE J369, ASTM D5132)

Fatigue Testing

Flexural Properties (-240ºF to 660ºF)

Gardner Impact

Glass Transition

Gloss (ASTM D523, D4039)

Heat Deflection by TMA (E2092)

Impact Strength

Kinematic Viscosity

Lap Shear Testing

Melt Flow Rate/Index

Melting Point

SEM-EDS for Fillers

Taber Abrasion

Tear Resistance of Films & Sheeting

Tear of Rubbers & Elastomers

Tensile Properties (-240F to 660F)

UV Exposure

ACCREDITATIONS

Click here for a complete list of accreditations and certifications for all IMR Test Labs locations.