Prepreg Composite Testing

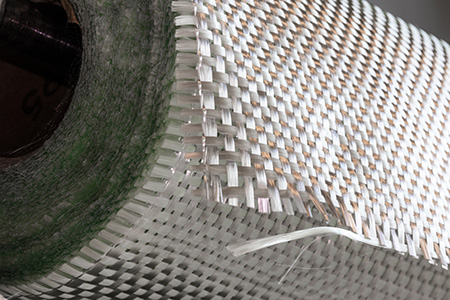

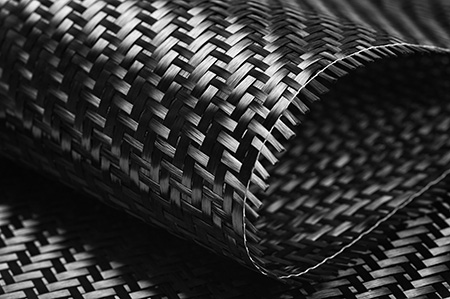

Prepreg CompositeTesting measures resin impregnation levels of fiber reinforced composites, or pre-impregnated materials. This data helps manufacturers and their suppliers make critical decisions about material properties, and how they will affect finished part quality, particularly for the aerospace and automotive industries.

Prepregs offer consistent resin content, and evaluating the resin impregnation level is important to processing the prepreg/tape lay-up material and the finished composite part quality because of its effect on prepreg lay-down efficiency and air/volatile evacuation prior to and during the curing cycle.

Partial impregnation is a common practice used to manufacture prepreg materials for the defense industry while full impregnation is used for automated tape materials.

To find out more about IMR's prepreg testing capabilities, click on the button below.

Prepreg Composite Testing - Material Analysis

Analyzing prepreg composite materials ensures quality, performance characteristics, and mechanical properties and can be performed using various analysis measurements such as:

Content Measurement of Resin

The percentage of resin content ensures the ratio to its reinforcing fibers is satisfactory for optimal performance.

Drapability

Determining the prepreg’s ability to conform to molds or shapes is essential for handling during lay-up.

Tack

Assesses the tackiness of the prepreg composite material.

Curing

Performance when exposed to heat and pressure during curing, to understand the appropriate curing cycle for the application.

Dimensional Accuracy

Examine the stability and coefficients of thermal expansion.

Potential for Degradation or Delamination

Assessment of moisture absorption in humid environments resulting in degradation or delamination.

Mechanical Properties

Assessment of performance, stiffness, and mechanical, tensile, and flexural strengths.

Material Compatibility

Will the prepreg react to adhesives and bonding agents.

Prepreg Analysis Benefits

Prepreg Testing is a crucial part of manufacturers' decisions about which materials are suitable for specific applications so that the finished product is reliable, consistent, and high-quality. With the properly tested material, risk is mitigated, and customer satisfaction is increased. Some key benefits to prepreg testing of composite materials include:

Material Specifications

Resin content and fiber reinforcement are studied in order to determine the mechanical properties of the prepreg composite materials. Structural strengths are measured by verification of adhesion of prepreg composites with other materials.

Quality

Standards of quality and specifications are strict for manufacturing industries, and prepreg composite testing ensures materials meet the standards and specifications prior to use.

Curing Cycle Control

By testing prepreg composites and determining the ideal curing cycle, end-users ensure their materials are properly processed in order to reach a final product.

Performance

Data obtained through testing mechanical and thermal prepreg composite properties lends predictions on how the material will perform with various factors such as load, temperature, and environment.

Customization

Prepreg composites can be tailored to meet specific requirements in order to customize the final product for it’s intended application, ensuring thermal resistance, weight, and strength are ideal.

Research and Material Selection

Through testing, prepreg composite formulations can be compared, and composite materials can be improved, furthering the development of certain facets within manufacturing industries that utilize these materials.

The length of a prepreg test depends on which test is being performed, the complexity of the prepreg material, and how many tests are being performed. The time ranges from as little as a couple of hours to several days. The experts at IMR Test Labs can provide a testing plan and a time estimate based on the plan.

The amount and format of material required for a prepreg test depends on how many and which tests are performed. Contact an IMR Test Labs expert for further details. Guidelines will be assessed, sample size will be determined, and format or other relative details will be identified.

Simple prepreg tests can be relatively inexpensive and depend on the amount of material being tested. More complex prepreg tests are more costly due to the requirement of specialized equipment. IMR Test Labs provides a detailed quote for all testing methods. Discounts may apply to multiple tests or scheduled ongoing testing services.

IMR Test Labs company headquarters in Ithaca, NY has extensive experience in prepreg composite testing.

POLYMER CHARACTERIZATION SERVICES

Accelerated Aging (Heat, Fluids)

Bond Strength

Brookfield Rotational Viscosity

Coefficient of Expansion

Coefficient of Friction

Composite Testing

Compression Set

Compressive Properties (-240ºF to 660ºF)

Dynamic Mechanical Analysis (DMA)

Failure Analysis

Flammability (UL94, FMVSS 302, ISO 3795, SAE J369, ASTM D5132)

Fatigue Testing

Flexural Properties (-240ºF to 660ºF)

Gardner Impact

Glass Transition

Gloss (ASTM D523, D4039)

Heat Deflection by TMA (E2092)

Impact Strength

Kinematic Viscosity

Lap Shear Testing

Melt Flow Rate/Index

Melting Point

SEM-EDS for Fillers

Taber Abrasion

Tear Resistance of Films & Sheeting

Tear of Rubbers & Elastomers

Tensile Properties (-240F to 660F)

UV Exposure

ACCREDITATIONS

Click here for a complete list of accreditations and certifications for all IMR Test Labs locations.

Industries That Use Prepreg Composite Testing

Many industries utilize prepreg composite materials in their products or processes, and prepreg composite testing is used to ensure quality, safety, and reliability. Some industries that utilize prepreg composite testing include:

Automotive Industry

Lightweight and high-strength body panels, chassis elements, and interior parts are prepreg tested.

Wind Energy

Turbine blades are often prepreg composite materials due to their lightweight composition and performance under certain conditions.

Military

Prepreg testing ensures compliance with rigid specifications for the manufacture of aircraft, equipment, and vehicles.

Aerospace

Prepreg composites are used to make components of aircraft, such as wings and fuselages, to ensure performance and lightweight.

Industrial Machinery

Machine components must be structurally sound and lightweight. Machine frames and components are made with prepreg composites.

Medical Devices

Performance and safety are critical in medical components made of prepreg composites, such as prosthetics, orthopedic items, and braces.

Electronics

Prepreg composites are used to create small, lightweight, and durable electrical components.

Marine

Prepreg composites are used in both boat parts, such as hulls, and marine applications, such as docks. Testing ensures the materials are lightweight and can function in harsh marine environments.

Construction

Prepreg Testing ensures building materials, such as building structures and bridges, are compliant with industry standards and safe for application.