Scanning Electron Microscopy | SEM Analysis Services

WHAT IS SEM ANALYSIS?

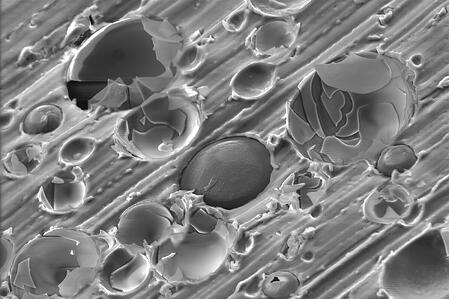

SEM Analysis (Scanning Electron Microscopy) consists of concentrating a focused beam of high-energy electrons, which generates a number of signals at the surface of solid specimens: metals, polymers, or composites. These signals, which are gleaned from electron-sample interactions, relay important information about the sample, such as texture, microstructure, the processes performed on the material during manufacture, and whether the material meets the needed specifications to ensure optimal durability in the intended application.

SEM Analysis is performed quickly and the microscopes used in this process are able to generate data in a sophisticated digital form.

SEM Analysis is used in research, quality control, and characterization for several industries including semiconductor manufacturing, biology, nanotechnology, forensics, geology, and materials science.

Benefits of SEM Analysis

Sample Versatility

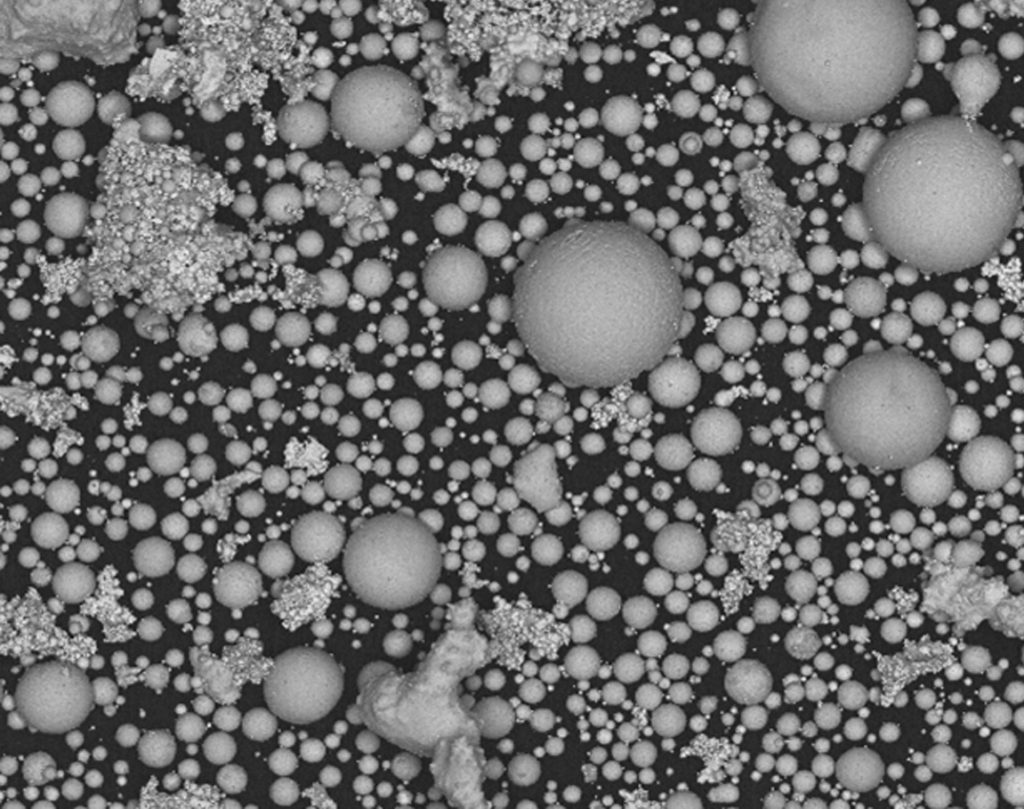

SEM can analyze a variety of materials, including powders, solid materials, coatings, biological specimens, and fibers.

3D and High-Resolution Imaging

High-Resolution imaging provides a detailed visualization of surface features and a 3D representation of the sample surface is created by capturing many images at different angles.

Elemental Analysis

Elemental composition is revealed by using EDS (energy-dispersive X-ray spectroscopy) or WDS (wavelength-dispersive X-ray spectroscopy) detectors. EDS analysis is used to supplement the high resolution, high depth of field images with as elemental analysis of the materials in the image field.

For more information on IMR's SEM capabilities, or to request a quote, click on the buttons below.

METALLURGICAL LAB SERVICES

Carburization

Case Depth

Certified Weld Inspections

Coatings Evaluations

Coating Thickness by XRF, SEM, Cross Section

Case Depth

Depth of Decarburization

Determination of Delta Ferrite Content

Determination of Volume Fraction by Point Count

Effective Case Depth

Failure Analysis

Fastener Discontinuities

Fluorescent Impregnation of Porous Coatings

Fractography

Fracture Mechanics

Grain Size

Inclusion Content/Rating

Intergranular Attack

Intergranular Oxidation

Light Microscopy - Macro, Micro & SEM Photography

Macroetching

Microetching

Microhardness (Knoop, Vickers, MacroVickers)

Microstructure

Orientation in Microstructure

Particle Analysis (Distribution, ID, Size)

Phase Volume Determination

Pipeline Integrity

Plating Evaluations

Plating Thickness

Porosity of Metals, Ceramics & Composites

Prior Austenitic Grain Boundary Determination

Replication (ASTM E1351)

Quantitative Image Analysis

SEM Analysis

Surface Evaluation (Dubpernell Active Site Test ASTM B456 Appx 4)

Surface Topography

Thermal Spray Coating Analysis

Titanium Beta Transus Determination

Weld Qualification & Testing

SEM Imaging and Analysis

There have been many advances in SEM technology due to improvements in lens design, high-brightness electron sources, new detectors, and electronic signal processing. There are many different types of scanning electron microscopes designed for specific purposes ranging from routine morphological studies to high-speed compositional analyses.

SEM Imaging: Custom Solutions

If your needs for SEM analysis transcend conventional testing protocols, contact us to create a custom testing process.

RELEVANT ACCREDITATIONS

Click here for a complete list of accreditations and certifications for all IMR Test Labs locations.

FAQ's

Coatings, fibers, powders, solid materials and biological specimens can be tested with SEM Analysis.

Surface roughness, crystallographic information, topography, particle size, and elemental composition are all revealed through SEM analysis.

Analyses can be completed in as little as a few hours.