Chemical analysis of metals validates that the candidate material is appropriate for the intended end use. ICP analysis, OES analysis, gravimetric analysis, SEM-EDS analysis and XRF analysis are a few common qualitative and quantitative methods of determining material composition of metals.

IMR's labs also offers combustion methods including carbon, sulfur, hydrogen, oxygen and nitrogen testing to check all of the elemental properties of your metals. IMR offers semi-quantitative and fully quantitative analyses of metallic materials as well as PMI testing in our labs or at your location.

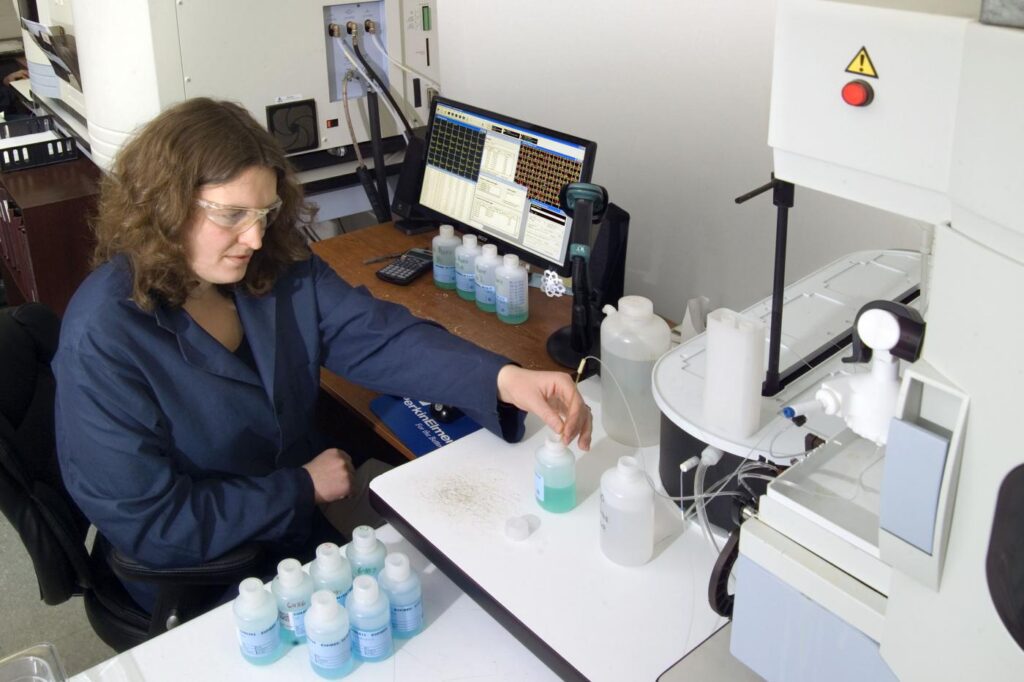

We have extensive preperation labs to get your samples ready for analysis, providing accurate results, fast. We are trained in the latest microwave preparation techniques, as well as classical methods of wet chemistry. Our equipment and lab personnel can detect trace elements at very low concentrations.

From simple steels to complex nickel and titanium alloys, IMR will provide you a clear, concise report listing the elements included, your results and compared to your specification, if provided. We can also identify trace elements and unknown materials to UNS specifications if the need arises.

Learn more about our metals chemistry capabilities below or request a quote today.

CHEMICAL TESTING OF METALS ANALYTICAL METHODS

ICP-MS ANALYSIS

ICP-MS (Inductively Couple Plasma - Mass Spectrometry) provides analysis of metals down to the parts per billion level for solutions and the parts per million level on solid samples. Our standard turnaround is 3-5 days depending on the sample and analysis needed.

ICP-AES ANALYSIS

ICP-AES analysis (Inductively Coupled Plasma - Atomic Emission Spectroscopy) provides analysis of metals down to trace levels. We can provide trace element analysis results as low as 50 ppm depending on your material, sample size and elements requested. ICP analysis can work with smaller samples due to the fact acid digestion is required. Our standard turnaround is 3-5 days depending on the complexity of the digestion needed to put the sample into solution.

OES ANALYSIS

OES Analysis (Optical Emission Spectroscopy) provides analysis of metals down to trace levels and is less destructive than an ICP analysis. While it requires prepping the flat surface with some grinding to ensure a clean burn, it leaves the sample relatively intact in case further analysis is needed.

This service is preferable if you have a larger sample size because it is less expensive than a digestion method such as ICP-AES. The ideal sample is 1" x 1" flat surface, but depending on the material and elements needed, smaller samples can be accommodated. Standard turnaround is 3 days or less.

SEM-EDS OR SEM-EDX

SEM-EDS Analysis (Scanning Electron Microscopy - Energy Dispersive Spectroscopy) is particularly useful with a very small sample such as in a failure analysis where you may only have debris or shavings. While some light elements cannot be detected, our team can often give you a statement that the sample is or is not consistent for the elements checked with a desired specification.

XRF ANALYSIS

Wavelength-Dispersive X-Ray Fluorescence Spectroscopy (WD-XRF) offers compositional analysis of various metals. The method requires a solid sample able to cover a 29mm diameter opening; however, smaller samples can be accommodated. Note that some light elements (such as boron, beryllium, etc) cannot be detected via this method.

Like OES this method is fast, somewhat less expensive than ICP, and is relatively non-destructive. We currently offer this service from our Ithaca, NY lab on stainless steel, copper, nickel, titanium and cobalt alloys. Standard turnaround is 3 days or less.

CHEMICAL ANALYSIS OF METALS SERVICES

Carbon Analysis

Hazardous Substance Testing

Heavy Metals Analysis

Hexavalent Chromium Analysis

Hydrogen Analysis

ICP-AES Analysis

ICP-MS Analysis

Material Verification

Nitrogen Analysis

OES Analysis

On-site PMI

Oxygen Analysis

PMI Testing (Positive Material ID)

Precious Metal Assay

Purity Testing

SEM-EDX Analysis (SEM-EDS)

Semi-Quantitative Analysis

Sulfur Analysis

Trace Element Analysis

Unknown Material Identification

XRF Analysis