Metallurgical Analysis and Metallography Services

Metallurgical analysis reveals the condition and makeup of materials with macro, micro and SEM examinations. These analyses reveal microstructure, processes performed on the material during manufacture, and whether or not the materials meet the required specification(s) to ensure durability in the intended use.

IMR's experienced metallurgists evaluate defects, determine structural features, identify alloys, evaluate the effects of heat treating, and ensure materials characteristics align with specifications. Failure cause analysis services can be provided when material performance doesn't meet specifications..

Our facilities offer a wide range of testing from routine microstructures and microhardness surveys, to unique studies including electrochemical corrosion simulations, mercurous nitrate testing and more. Routine testing of microstructures, coatings evaluations, hardness surveys and more are available. Most jobs can be turned around in three days or less and we have special pricing for routine work. You get the same high-quality results and reports fast.

In addition, we offer aggressive machining evaluations, thermal spray coatings evaluations, corrosion evaluations and comparative material analyses.

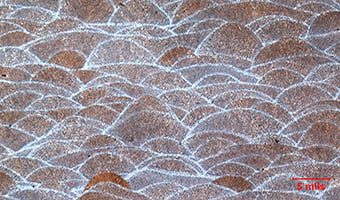

Many industries rely on thermal spray coatings to ensure durability of parts that will be subjected to wear, high heat, corrosion and other harsh in-service conditions.

Increased machining speeds can often affect the characteristics of feedstock material. High speeds generate more heat, which can have an impact on both the tool and the work piece.

IMR's metallurgical team is equipped to identify corrodents and other environmental variables that are directly responsible for corrosion attacks.

Microhardness testing produces data identifying individual phases and orientation effects..

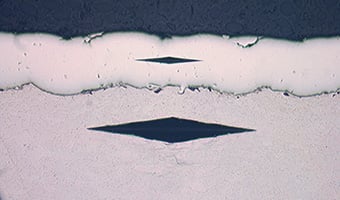

Metallography is the art and science of preparing test samples for accurate evaluation of a materials microstructure.

Welder qualification and weld evaluation for OEM's and vendors. Qualification to the AWS, European Directive, and ASME standards.