IMR's Mechanical Testing Laboratory Services are processes used to determine the physical make-up of a material. Testing is used to determine a material's hardness, corrosion resistance, performance under applied pressures & stresses, bonds to other materials, and more. IMR Test performs a wide range of mechanical testing methods to evaluate metals, polymers, composites and finished products. Most testing is completed in three days or less for routine tensile, hardness and charpy impact testing. More complex tests like fatigue, fracture toughness, and product testing require a testing plan created with input from our testing experts, to achieve your testing goals..

Mechanical Testing Environments

Our fatigue testing frames simulate various use environments in high and low cycle modes. These frames also perform fracture toughness and crack growth experiments. We perform HCF (High Cycle Fatigue) and LCF (Low Cycle Fatigue) testing and analysis of critical jet and rocket engine materials. Most testing is completed in three days or less for routine tensile, hardness, and charpy impact testing.

Mechanical Testing - Analysis of Materials

•Metals •Finished Products •Non-Metallics •Polymers •Composites •Coatings

MECHANICAL TESTING TYPES

IMR's Creep and Stress Rupture testing lab performs these tests to measure material strength under constant stress, temperature..

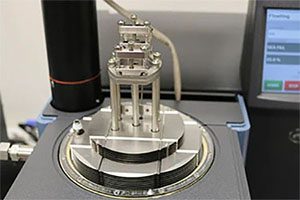

Fatigue testing is conducted to examine and evaluate the resistance to cracking of all types of materials under cyclic loading conditions..

Tensile testing is a common test method where a sample is placed in grips and subjected to a controlled tensile force until it fails.

Fracture toughness calculates the ability of a material to resist cracking under increasing loads.

Impact testing provides information on the material's ductility, as well as the temperature-dependent ductile-brittle transition.

Bond pull testing accurately measures bond strength, of thermal spray coatings.

DMA testing measures the physical properties of solids and polymer melts, reports modulus and damping.

Welder certification and weld evaluation to AWS, European Directive, and ASME standards.

Benefits of Mechanical Testing Analysis Services

Energy Performance

- Identify energy deficiencies of materials

- Optimize energy use with proper materials

Operational Integrity

- Ensure material suitability for an application

- Determine life expectancy of selected materials

Quality Control

- Qualify material integrity analysis

- Leverage environmental exposures against material integrity

Vulnerability Identification

- Determine material deficiencies in advance of use

Streamline Product Design

- Learn and apply material properties to future designs

- Innovate technological advancements with materials

Mechanical Testing Service FAQs

Q) What is mechanical testing?

A) Mechanical testing evaluates a material's physical properties, such as strength, hardness, toughness, and fatigue resistance, to determine how it performs under various forces and conditions. These tests help ensure materials meet industry standards and are suitable for their intended applications.

Q) What is on a mechanical test report?

A) Material identification, method of testing and standard (ASTM, ISO), testing condition parameters (temperature, load, and strain rate), and results (tensile strength, yield strength, elongation, hardness, and fatigue life.

Q) How long do Mechanical Testing Services typically take?

A) Most testing is completed in three days or less for routine tensile, hardness, and charpy impact testing. However, the time frame for more complicated testing ranges can take a week or more, unless expedited by request.

Q) What type of Mechanical Testing report is provided?

A) IMR Test Labs provides a comprehensive analysis report for all types of mechanical testing laboratory services and varies depending upon the test type. Click here for a sample PDF report.

Q) Can you perform Mechanical Testing at all IMR facilities?

A) Each of IMR’s Mechanical Test Labs mechanical testing services laboratories can perform several types of mechanical testing. Click each location below for a comprehensive overview of the services provided.

Q) How do I get a quote for Mechanical Testing Services?

A) The experts at IMR Test Labs are happy to consult on what type of testing you need, how long it will take, the analysis you will receive, and the associated cost. Call (888) 464-8422 to speak to an expert today or contact us by email.

Q) What industries do Mechanical Testing Services serve?

A) IMR Test Labs is well equipped and proud to serve the following industries: aerospace materials, additive manufacturing, energy, automotive & transportation, nuclear, and oil & gas. The industries we serve depend on the reliability, safety, and verification of the raw materials and components they use to ensure maximum efficiency and performance. Find out more about markets we serve.