IMR Materials Testing Technical Blog

7 Common Failure Mechanisms of Composite Materials

As non-metallic fabrication materials such as fiber-reinforced composites, polymers, and coatings continue to see increased usage in manufacturing applications where metallic materials are too heavy or too susceptible to corrosion, stakeholders ranging from design engineers to procurement professionals must understand the various problems and limitations that can arise if materials are not carefully selected. This understanding can be achieved through comprehensive failure analysis testing.

Failure analysis testing requires extensive expertise and knowledge across a wide range of materials and failure modes. Analyzing fatigue characteristics of materials in advance can give engineers an advantage before they ever begin prototyping and testing their designs, while post-failure testing can help designers correct design flaws or inadequate material choices.

Common Non-Metallic Failure Modes

There are a multitude of modes that can cause the failure of non-metallic materials, each with its array of potential causes. It should be noted that there is often overlap between modes and that similar failure modes can sometimes occur in metallic material. However, the ultimate effect on non-metallic material may present differently. Some of the most common modes discovered in non-metallic failure testing include:

1. Fracturing

A common failure mechanism in composites and polymers, fracturing often occurs cyclically and may not be noticeable until an object or material experiences failure. In many cases, fractures occur over time due to constant or cyclical stress on the object in question. This happens most often when an improper material that can’t handle necessary weights or stresses is chosen for an application, or when a design flaw focuses undue stress on one particular area of a component.

Example: A ceramic engine part becomes brittle after heat from engine operation causes thermal expansion. The weakened part then fractures during normal operation.

2. Fluid Aging

Fluid aging is sometimes referred to as “corrosion for composites,” and encompasses more common terms such as hydrolysis, acid hydrolysis, or alkaline hydrolysis. The term refers to chemical interactions between certain composites and water or other chemicals that may compromise the integrity of the original material. This process occurs over time, and as such may not be noticeable before failure.

Example: Fluid aging compromises the integrity of the internal wall of a plastic pipe over some time, but isn’t noticeable until the reaction causes a leak.

3. Thermal Aging

Composite materials used in applications where they are exposed to high temperatures can experience eventual degradation, so design engineers must select materials that have thermal tolerances appropriate to the intended application.

Example: A non-metallic protective coating melts or erodes under prolonged heat exposure, leaving the substrate exposed and susceptible to damage.

4. Fatigue

Fatigue and failure are often used interchangeably, but doing so isn’t a correct use of the terms. Fatigue is simply one failure mechanism, in which prolonged cyclical stresses cause undue or unexpected wear on a part until it ultimately fails.

Example: In composites, repeated support of extreme weights can cause fibers to tear. Similarly, in polymers, prolonged or cyclical exposure to weight or pressure can cause cracks that eventually lead to failure.

5. Creep

Creep is similar to fatigue. However, instead of cracks or tears, the part becomes slowly deformed through repeated exposure to stress or extreme temperatures.

Example: In fiber-reinforced composites, threads may not break under stress, but instead potentially stretch or bend due to cyclical increases in load exposure, which reduces the effectiveness of the overall part.

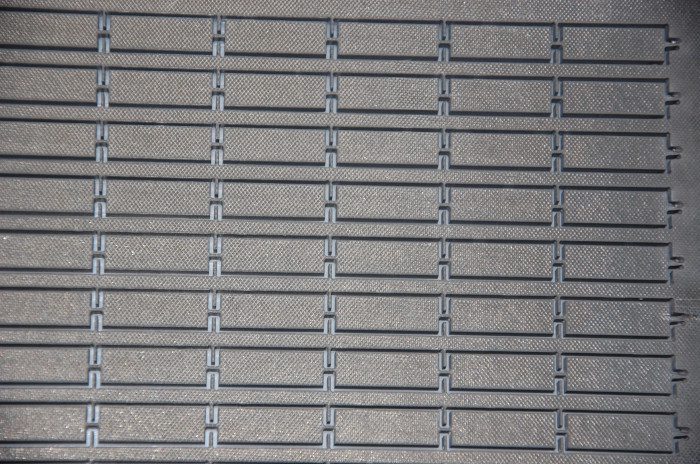

6. Delamination

This mechanism occurs when cyclical stresses or direct impact damage the bond between layers or fibers in composite materials. Fiber-reinforced composites rely on accurate layering for their strength, so delamination can severely compromise the material’s mechanical strength.

Example: A fiber-reinforced composite boat hull impacts an unexpected object at a high speed. While the damage may not be obvious, the hull’s integrity becomes compromised as the fibers break and the layers separate.

7. Material Selection/Composition

While not a failure mechanism itself, per se, material selection is crucial to the prevention of premature component failure. Improper material selection can result in any of the above failure mechanisms (which depends on the material). Failing to select the correct material with the appropriate molecular composition for the application can result in a range of problems, from shortened service life to unexpected critical failure.

PARTNER WITH IMR TEST LABS

At IMR Test Labs, we not only possess the ability to identify the failure mode of your metallic or non-metallic part but also the knowledge and analysis capability to help you determine the most suitable material for your design. Our highly educated team of chemists, engineers, and lab technicians use a range of equipment and years of expertise to provide the most comprehensive range of analytical services available to customers around the globe.