IMR Materials Testing Technical Blog

Fatigue Failure Analysis of Steel Pin

A 4150 steel pin was received for failure analysis; the fracture was determined to be due to rotating bending fatigue.

The sample was consistent with the supplied chemistry specification with the exception of a high sulfur value. This implies that the material was resulfurized for machinability.

The fracture occurred at a machined radius near the center of the pin. The machined radius exhibited rough machining lines which may have acted as crack initiation sites. A finer finish on the part would likely result in improved fatigue performance.

IMAGE CAPTIONS

Optical micrograph of the fracture surface. Beach marks (examples indicated by red arrows) are characteristic of fatigue.

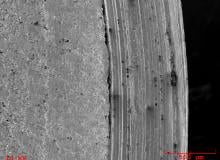

SEM view of the fracture surface with deep machining mark at the edge.

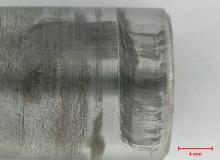

Wear marks on pin surface near the fracture.

Microstructure in the etched condition (2% Nital) consists of primarily martensite with sulfide inclusions.

To learn more about IMR’s Failure Analysis capabilities, click here.