OES ANALYSIS SERVICES

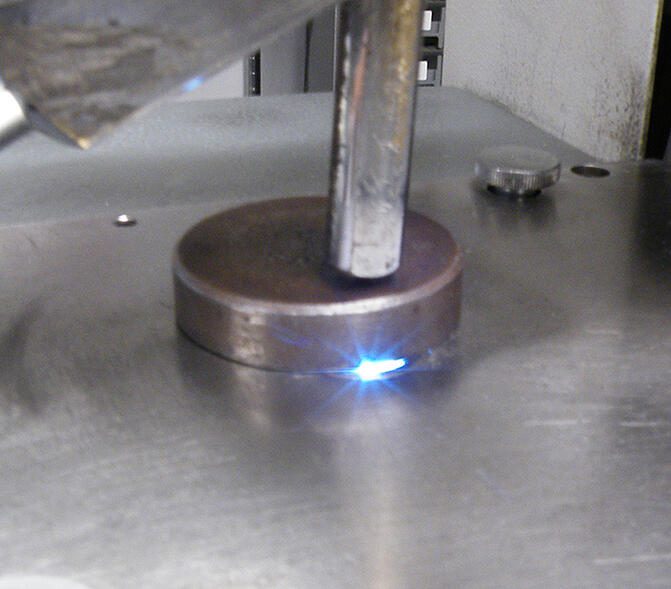

OES analysis uses an Optical Emission Spectrometer to make a quantitative measurement of the optical emission from excited atoms to determine analyte concentration. A solid sample is atomized by an arc-spark discharge which provides sufficient energy to promote the electrons of atoms into high energy levels.

The intensity of the light, which is proportional to the concentration of the element in the sample, is recalculated internally. The recalculation uses a set of calibration curves and is shown directly as a percent concentration of the element.

How OES Analysis Works

An optical emission spectrometer (OES) is a powerful analytical tool that can be used to characterize a wide range of materials, including metals, alloys and semiconductors.

OES is particularly well suited to the analysis of composite materials. It can provide information on both the elemental composition and the microstructure of the material. In composite material testing, OES can be used to identify the presence of impurities or defects, and to determine the distribution of elements within the material. This information is essential for quality control and for understanding the behaviour of the material under different conditions.

OES is a non-destructive technique that is quick and easy to use, making it an important tool for composite material testing. All analyses are NIST traceable through the use of certified reference materials. Typically element concentrations are reported to 0.01 wt%, however in some cases trace elements can be analyzed to ppm levels.

OES analysis (Optical Emission Spectroscopy) uses quantitative measurement of the optical emission from excited atoms to determine analyte concentration. A solid sample is atomized by an arc-spark discharge which provides sufficient energy to promote the electrons of atoms into high energy levels.

The intensity of the light, which is proportional to the concentration of the element in the sample, is recalculated internally from a stored set of calibration curves and is shown directly as percent concentration of the element.

OES ANALYSIS- MATERIALS TESTED

- ALUMINUM

- IRON

- NICKEL

- COBALT

- COPPER

- TITANIUM ALLOYS

Alloy Chemistry

Antimony Analysis (ICP)

Cadmium Analysis (ICP)

Carbon, Sulfur, Hydrogen, Oxygen & Nitrogen

Contamination ID

Contaminant/ Corrodent Analysis

Filler/Additive Analysis

FTIR

Halogen Analysis (IC)

Heavy Metals Analysis

Hex Chrome (UV-VIS)

ICP-AES Analysis

ICP-MS Analysis

Impurities Analysis

Ion Chromatography

Material Certification

Metal Purity

OES Analysis

On-site PMI

PMI Testing (Positive Material ID)

Particle Size Analysis

Percent Crystallinity

pH

Polymer Testing

Powder Diffraction

Powdered Metal Analysis

Precious Metal Assay

Quantitative Analysis

Resistivity (ASTM D1125)

SEM-EDS

Semi-Quantitative Analysis

Trace Element Analysis

Unknown Alloy Identification

Unknown Material Identification

XRD Analysis

XRF Analysis

OES analysis is performed quickly, easily, and is non-destructive to the material being tested. OES testing can be performed at IMR Test Lab facilities or onsite. OES Analysis provides accurate results.

OES analysis is typically performed in a few hours, with results generated immediately upon completion of the test.

OES analysis is a relatively inexpensive test option for the compositional analysis of materials. Contact us to find your nearest facility or request a quote

STANDARD TEST METHODS

- ASTM E 415 – Low Alloy and Carbon Steels

- ASTM E 1251 – Aluminum Alloys

- ASTM A 751 – 400 Series Stainless Steels

- ASTM E 1086 – 300 Series Stainless Steels

- ASTM E 1999 - Cast Irons (PTL)

RELEVANT ACCREDITATIONS

Click here for a complete list of accreditations and certifications for all IMR Test Labs locations.