CLEANLINESS TESTING

Cleanliness testing helps to mitigate issues during the manufacturing process. Very precise testing techniques are required to identify the source and composition of the contaminants.

CLEANLINESS TESTING-METHODS

Contaminant Identification & Analysis

Contaminants can come from a wide range of sources including oils from equipment, residues from human hands, smudges and streaks from manufacturing processes and corrosion from leaks of water, coolants and more.

- TOC (Total Organic Carbon) Analysis is a rapid examination of extracts for residual organic materials such as oils, cleaning agents, lubricants, etc.

- FTIR (Fourier Transform Infrared Spectroscopy) Analysis is used to identify organic materials such as oils, cleaning agents, plastic particulates, and packaging residue extracted from sample surfaces and internal passages.

- ICP Chemical Analysis identifies elemental contaminants in extracts, such as residual iron from tooling during cutting, as well as providing a thorough breakdown of metallic particulates.

- IC (Ion Chromatography) is an analytical technique that permits the identication in an aqueous solution.

- SEM-EDS (Scanning Electron Microscopy / Energy Dispersive X-ray Analysis) allows for high magnification examination of particulate and other debris removed during extraction procedures. Chemical analysis by EDS provides information on the elemental makeup of particles, allowing them to be traced back to their sources.

Gravimetric Testing

Gravimetric cleanliness testing involves:

- Washing the part to transfer particulate and other contamination from the part to the washing fluid.

- Filtering the washing fluid to transfer the contaminant to an analytical membrane filter of defined size.

- Weighing the change in filter mass to determine the contaminant mass.

- Reporting and analyzing results.

CLEANLINESS TESTING - INDUSTRIES

Medical Device- Testing Services

Cleanliness testing is critical step for any medical device intended for permanent implantation, as well as devices such as surgical instruments. These products must meet stringent cleanliness standards to minimize the risk of post-surgery complications. To ensure the viability of such devices, their surface cleanliness must be determined before they can be used in practical applications.

IMR's medical device cleanliness team utilizes various extraction and analytical techniques to characterize both particulate debris, as well as machining and cleaning residues, on implants and surgical devices.

We test for medical device cleanliness to the ASTM F 2459 standard, which covers extraction and gravimetric methods.

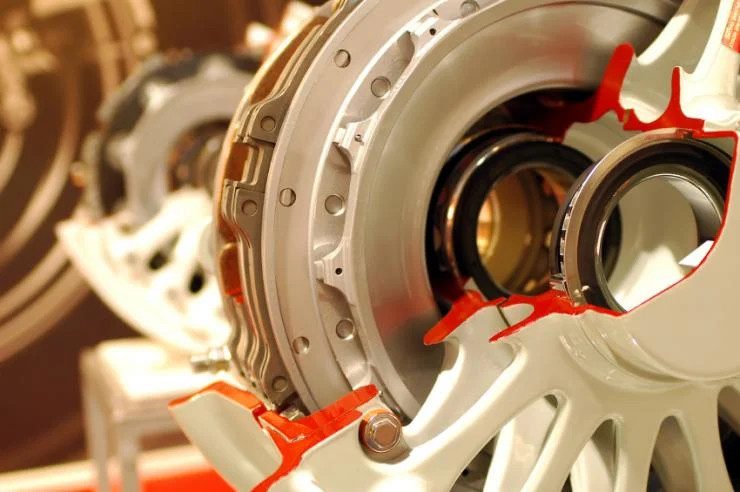

Transportation Industry- Contaminant Identification

Safety of transportation vehicle components is paramount. Cleanliness testing allows manufacturers to identify foreign residue or particles present in components and identify the contaminants.

Stringent testing is performed according to cleanliness standards in order to ensure that the components used are ideal for the application and that the end result is both strong and safe.

Transportation cleanliness testing is overseen by the American Society of Automotive Engineers (SAE).

Aerospace Manufacturing- Failure & Corrosion Prevention

Cleanliness testing performed in the aerospace industry helps to predict failure and ensures corrosion prevention.

Circuits, telecommunications, hydraulics, automation, fueling, and many other aspects of aerospace manufacturing and performance can be cleanliness tested.

Aerospace cleanliness testing is overseen by the American Aerospace Industry Association (AIA).

CLEANLINESS TESTING- STANDARDS

- ISO 10993- Part 12: Medical Device Testing

- ISO 16232 - Automotive Parts / Liquids

- ASTM F 2459 - Medical Devices

- ASTM E 1019

- ASTM E 1447

- ASTM E 1409

CLEANLINESS TESTING- FAQ

Cleanliness testing identifies foreign residues and particles, in order to determine whether their presence will affect the overall performance of a component or material.

Typically cleanliness testing can be performed in a matter of days and should it be necessary, expedited testing is available. Contact IMR Test Labs for more information.

Metals, non-metals, porous surfaces, polymers, and natural materials can all be tested for cleanliness. IMR Test Labs are able to test a variety of materials in any of our locations.

Alloy Chemistry

Antimony Analysis (ICP)

Cadmium Analysis (ICP)

Carbon, Sulfur, Hydrogen, Oxygen & Nitrogen

Contamination ID

Contaminant/ Corrodent Analysis

Filler/Additive Analysis

FTIR

Halogen Analysis (IC)

Heavy Metals Analysis

Hex Chrome (UV-VIS)

ICP-AES Analysis

ICP-MS Analysis

Impurities Analysis

Ion Chromatography

Material Certification

Metal Purity

OES Analysis

On-site PMI

PMI Testing (Positive Material ID)

Particle Size Analysis

Percent Crystallinity

pH

Polymer Testing

Powder Diffraction

Powdered Metal Analysis

Precious Metal Assay

Quantitative Analysis

Resistivity (ASTM D1125)

SEM-EDS

Semi-Quantitative Analysis

Trace Element Analysis

Unknown Alloy Identification

Unknown Material Identification

XRD Analysis

XRF Analysis

RELEVANT ACCREDITATIONS

Click here for a complete list of accreditations and certifications for all IMR Test Labs locations.