Metallurgical analysis reveals the microstructural condition and makeup of your materials with macro, micro, and SEM examinations.

Along with microstructure, these analyses reveal information on processes performed on the material during manufacture and whether or not the materials meet the required specification(s) to ensure durability in the intended use.

IMR's experienced metallurgists evaluate defects, determine structural features, identify alloys, evaluate the effects of heat treating, and ensure materials characteristics align with specifications. Failure cause analysis services can be provided when material performance doesn't meet specifications.

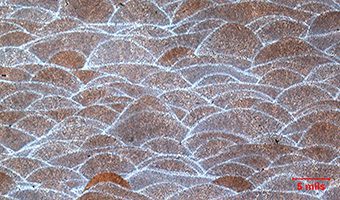

At our metallurgical analysis laboratories, we use advanced metallographic polishing techniques, leading to accurate analyses of base metal, alloy, or coating. We offer aggressive machining evaluations, thermal spray coatings evaluations, corrosion evaluations and comparative material analysis.

For more information on IMR's metallurgy capabilities, contact us here, or click the button below to request a quote.

Metallurgical Analysis of Properties

- Microstructure

- Porosity

- Grain Size

- Coating Application

- Corrosion

- Hardness

METALLURGICAL TESTING METHODS

Many industries rely on thermal spray coatings to ensure the durability of parts that will be subjected to wear, high heat, corrosion, and other harsh in-service conditions.

Increased machining speeds can often affect the characteristics of feedstock material. High speeds generate more heat, which can have an impact on both the tool and the workpiece.

IMR's metallurgical team is equipped to identify corrodents and other environmental variables that are directly responsible for corrosion attacks.

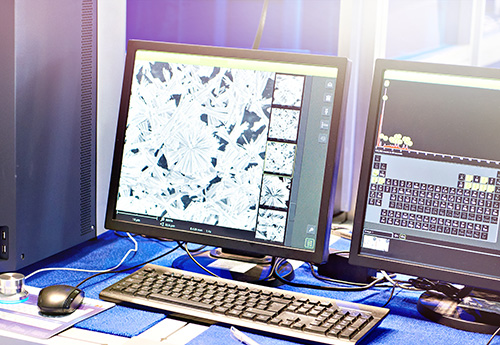

SEM Analysis is performed quickly and the microscopes used in this process are able to generate data in a sophisticated digital form.

Microhardness testing produces data identifying individual phases and orientation effects.

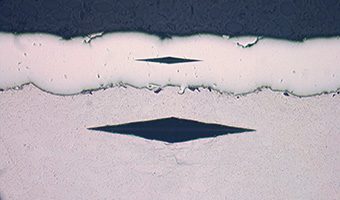

Welder qualification and weld evaluation for OEM's and vendors. Qualification to the AWS, European Directive, and ASME standards.

Metallography is the art and science of preparing test samples for an accurate evaluation of a material's microstructure.

METALLURGICAL ANALYSIS LABORATORY - Benefits of Using IMR Test Labs

- METALLOGRAPHIC POLISHING TECHNIQUES - advanced metallurgical analysis with reporting on base metal, alloy, or coatings. A vast array of specialty preparations.

- EXPERTISE - highly trained, experienced, lab technicians, engineers, and metallurgists. Images and data are provided on even the most challenging sample materials.

- EQUIPMENT LABS - state of the art, cutting-edge current technologies, including routine microstructure and microhardness testing, electrochemical corrosion simulations, mercurous nitrate testing, and more.

Metallurgical Analysis Laboratories FAQ’s

Metallurgical analysis reveals the microstructural condition and makeup of your materials with macro, micro and SEM examinations.

IMR Test Labs offers special pricing for routine work. You get the same high-quality results and reports fast, typically within 3 days. Routine testing offerings include microstructures, coatings evaluations, hardness surveys, and more.

If you have failed parts, metallurgical failure analysis is the best insight into the method of failure and possible causes. The analysis provides clear, concise reports explaining the step-by-step investigation, findings, causes and high-quality color images. With the support of our non-metallics failure analysis group, we are prepared to analyze your mixed material failures.

IMR Test Labs has 5 locations and the testing you require can be performed in less than a week and in most cases, faster. Expedited services are also available should the need arise.

The information obtained in IMR Test Lab metallurgical reports can aid in research and development projects. We offer aggressive machining evaluations, thermal spray coatings evaluations, corrosion evaluations and comparative material analyses. Our reports are clear and concise, providing you side-by-side results so you can make informed business decisions and determine how comparable different materials, material lots or manufacturers are.

Our litigation support includes expert witness testimony, witnessed testing and technical disposition.

METALLURGICAL ANALYSIS- LAB SERVICES

Alpha Case

Carburization

Case Depth

Certified Weld Inspections

Coatings Evaluations

Coating Thickness by XRF, SEM, Cross Section

Depth of Decarburization

Determination of Delta Ferrite Content

Determination of Volume Fraction by Point Count

Effective Case Depth

Failure Analysis

Fastener Discontinuities

Fluorescent Impregnation of Porous Coatings

Fractography

Fracture Mechanics

Grain Size

Inclusion Content/Rating

Intergranular Attack

Intergranular Oxidation

Light Microscopy - Macro, Micro & SEM Photography

Machining Evaluations

Macroetching

Microetching

Microhardness (Knoop, Vickers, MacroVickers)

Microstructure

Orientation in Microstructure

Particle Analysis (Distribution, ID, Size)

Phase Volume Determination

Pipeline Integrity

Plating Evaluations

Plating Thickness

Porosity of Metals, Ceramics & Composites

Prior Austenitic Grain Boundary Determination

Replication (ASTM E1351)

Quantitative Image Analysis

SEM Analysis

Surface Evaluation (Dubpernell Active Site Test ASTM B456 Appx 4)

Surface Topography

Thermal Spray Coating Analysis

Titanium Beta Transus Determination

Weld Qualification & Testing

METALLURGICAL ANALYSIS- CORROSION INVESTIGATION

Corrosion Failure Analysis

Dezincification Testing

Electrochemical Corrosion Testing

Environmental Stress Cracking (ESC)

Formicary (Ant’s Nest) Corrosion Evaluation

General and Pitting Corrosion Testing

Heat & Fluid Aging

Mercurous Nitrate Testing

Passivation Testing of Medical Components

Potentiodynamic Corrosion

Residual and Assembly Stress Testing of Copper Alloys

Sensitization Testing

Stress Corrosion Cracking (SCC)

METALLURGICAL ANALYSIS- SPECIALTY MATERIAL PREPARATION

Techniques

2 and 3 part Chemical Etching

AC Electrolytic Etching

Non-routine DC Electrolytic Etching

Vibratory Polishing

Commercially Pure and Medical Grade Titanium Alloys

Beryllium and Alloys

Antimony

Bismuth

Cadmium

Indium

Thallium

All High Purity Metals

Aluminum

Cobalt

Iron

Nickel

OFE Copper

Platinum Metal Group & Alloys

Iridium

Osmium

Palladium

Platinum

Rhodium

Ruthenium

Refractory Pure Metals and Alloys

Chromium

Molybdenum

Rhenium

Tantalum

Tungsten

Vanadium

Odd Metals and Alloys containing significant amounts of

Lead

Magnesium

Manganese

Tin

Zinc

Precious Metals and Alloys

Gold

Silver

Ceramics

Boride

Nitride

Oxide

Specific Difficulty

6061 Al Grains

Elgiloy

FSX414

Inconel 625

Haynes 25

Haynes 188

L605

Nitinol

Stellites

X-40

Very Difficult

Hafnium

Niobium

Zirconium