Metal Hardness Tests

Hardness testing is a basic mechanical test used to verify that metallic raw materials meet specifications, or it can be used as a quick check for materials that aren't performing as expected. The determination of whether a material is suitable for a given application or to the particular treatment to which it will be subjected is a key component of product development.

Rockwell Hardness Test

Rockwell hardness tests quantify the resistance of a material to plastic deformation, measure the indentation area, and are available as micro-indentation or macro-indentation.

Rockwell Hardness Tests (A, B, C, F, L, 15N, 30N, 45N, 15T, 30T, 45T, E, 15Y)

Brinell Hardness Test

Similar to the Rockwell hardness test, a Brinell hardness test uses a heavier test metal and creates a larger indentation in the sample material, and measures only the indentation.

Brinell Hardness (500, 1000, 1500, 3000Kgf)

Additional Hardness Tests

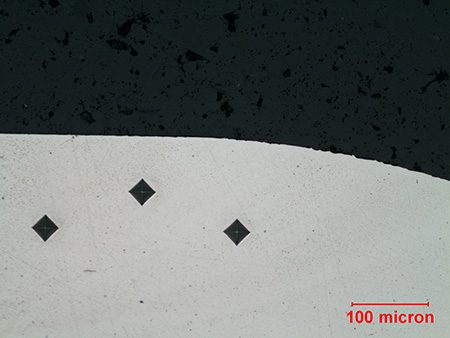

Microhardness:

- Macro Vickers - additional factor of relationship to distance is measured

- Macro-Vickers Microhardness (1-10kg)

- Vickers - measures largest scale of all hardness tests

- Vickers Microhardness (10-1000gf)

- Knoop - for fragile materials, less indentation to the sample material

- Knoop Microhardness (10-1000gf)

Non-Metallic Hardness Tests

- Macro Vickers - additional factor of relationship to distance is measured

- Macro-Vickers Microhardness (1-10kg)

- Vickers - measures largest scale of all hardness tests

- Vickers Microhardness (10-1000gf)

- Knoop - for fragile materials, less indentation to the sample material

- Knoop Microhardness (10-1000gf)

MECHANICAL TESTING METHODS

Abrasion (Taber)

Adhesion (Peel) Testing

Bend Testing

Bond Strength Testing

Charpy Impact Testing (-320°F to 450°F)

Climbing Drum Adhesion of Sandwich Composites

Coating Adhesion

Coating Shear Fatigue

Coefficient of Thermal Expansion by TMA

Composite Testing (Fiber Reinforced)

Compression Set

Compressive Properties

Core Shear Properties of Sandwich Construction by Beam Flexure

Creep and Stress Rupture Testing

DMA (Dynamic Mechanical Analyzer)

Ductility

Elastic Modulus

Fatigue Testing

Filled Hole Tension & Compression

Flattening

Flat-wise Tensile Testing

Flexural Properties

Floating Roller Peel Strength

Fracture Mechanics

Gel Time

Hardness (Rockwell, Brinell, Durometer, Shore, Barcol, Knoop, Vickers, Macro Vickers)

Heat Aging

Heat Deflection by TMA

Heat Treatment (furnace to 2100°F)

Hydrogen Embrittlement

Hydrostatic Pressure

Indentation Toughness

Interlaminar Shear

Jominy Hardenability

Lap Shear Testing

Machining & Specimen Preparation

Materialography

Modulus of Rupture (MOR)

n-Value (Strain Hardening Exponent)

Open Hole Tension and Compression

Pipeline Integrity Testing

r-Value (Plastic Strain Ratio)

Residual Strength of Composites After Impact

Rotating Beam Fatigue

Shear Testing of Rivets to ASTM B565, Single/Double

Short Beam Strength

Shot Peen Qualification

Single-Edged Notched beams (SENB)

Slow Strain Rate (G129)

Specimen Conditioning

Strain Gaging

Surface Roughness (ANSI/ASME B46.1)

T Peel Strength

Tear Resistance of Films & Sheeting

Tear - Rubbers & Elastomers

Tensile Testing

Torsional and Axial Fatigue (200 lb)

Tube Testing (Tensile, Flare, Hydrostatic)

Welder & Procedure Qualification

Wire/Spring Testing (Wrap, Coil, Bend)

Young's, Tangent and Chord Modulus (Room Temperature)

RELATED HARDNESS TESTING SPECIFICATIONS

ASTM A370

ASTM B578

ASTM D2240

ASTM D2583

ASTM E10

ASTM E18

ASTM E384

ASTM F606 / F606M

ISO 868

SAE J429

SAE J995

...and more

INDUSTRIES SERVED BY METAL HARDNESS TESTING

- Aerospace

- Automotive

- Energy

- Manufacturing

- Medical

- Metal Foundries

- Nuclear Power

- Petroleum

RELEVANT ACCREDITATIONS

Click here for a complete list of accreditations and certifications for all IMR Test Labs locations.